Our engineering team understand the nature of conveyor system dynamics in mining applications – this is crucial in applying the right boot end design for each individual project

NEPEAN Conveyors have the technical experience with all types of boot end systems commonly used in the mining industry.

A Full Range of Proven Designs:

Trunk Tail Frames

Robust, clean-loading inbye terminal points for development conveyors that are shuttle-car and feeder-breaker friendly.

Low load height accommodates more load options and the round bar

design is safe, maintenance free and protects conveyor belt covers.

Simple, strong inbye anchor points for trunk conveyors and drifts. Guarded to AS4024.3610, the compact tail frame design allows rapid relocation inbye, saving downtime. Loadable boot ends for trunk conveyors are also available, whether receiving material from a feeder-breaker or a high production rate trunk conveyor.

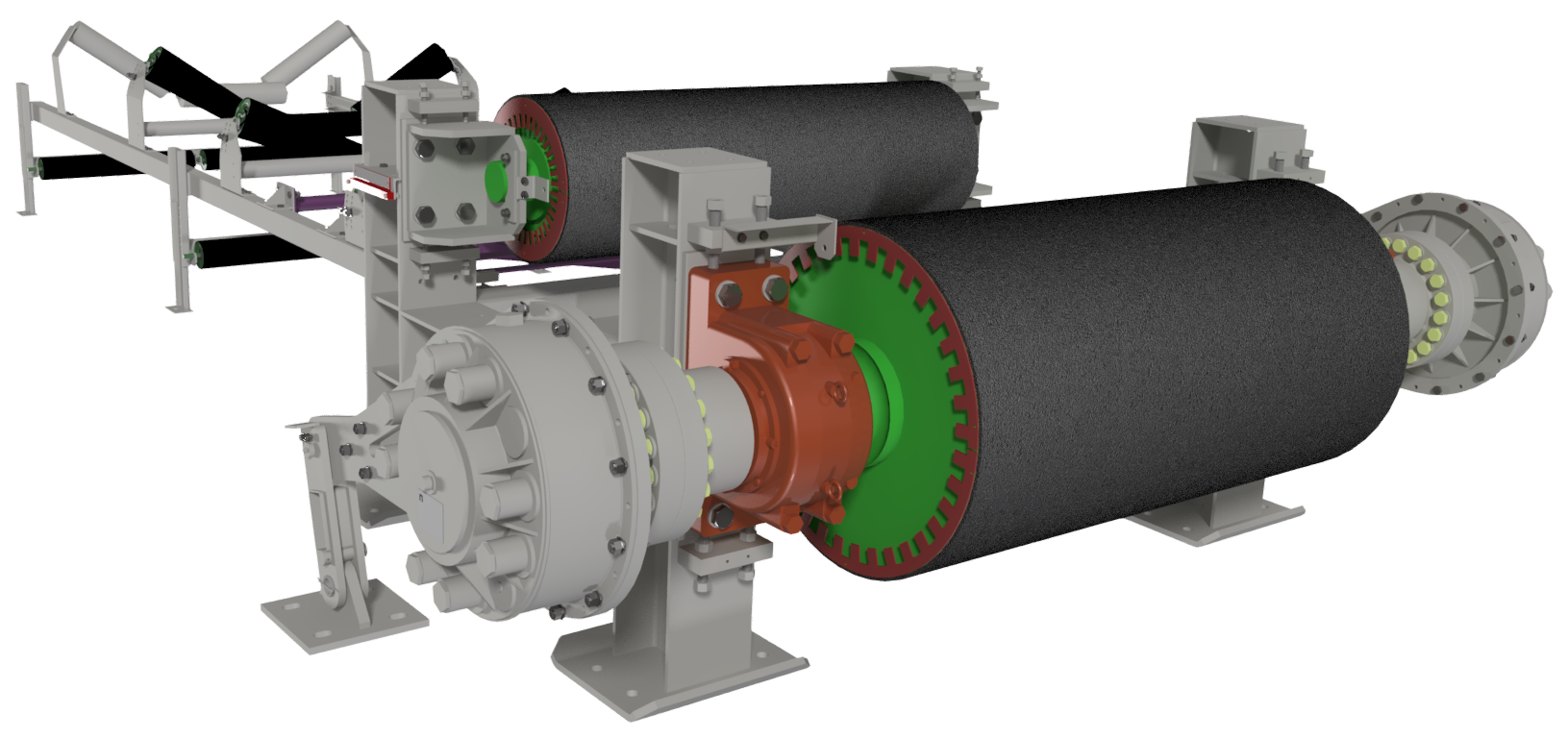

Braking Tail Frames

Coupled with high torque hydraulic braking systems, braking tail frames offer complete control of downhill and regenerative conveyor systems.

Tail frame braking protects the loop take-up from the large braking belt tensions. Braking tail frames are capable of producing up to 1200kW of braking power and can be combined with braking trippers to safely and accurately brake any downhill conveyor system.